You may know the origin of the HORST Dreidel but do you know how we make them?

Each dreidel is manufactured in two parts.

The Body: is made complete on a CNC Swiss screw machine. We use titanium, stainless steel, or aluminum bar stock. This round bar comes in lengths of up to 12 feet (3.6 meters). We turn the tip, mill the square, drill the hole, and tap the threads…all in one operation on this multi-axis machine.

We perform a tumbling and deburring process to remove the sharp edges and polish the surface.

We work with key suppliers who perform the aluminum anodizing process. Some of the titanium dreidels are anodized in house and some of them are coated at a supplier.

Some of the dreidels are marked in house and some of them are laser marked at a key supplier.

The Stem: the stem blank is made on a CNC Swiss screw machine. Even though we are capable of producing it complete, we opt to perform secondary operations for an even higher quality part. The blank shape is turned from a solid piece of round bar stock. We also drill the cross-hole.

The stems go through a light tumbling operation to remove any sharp edges.

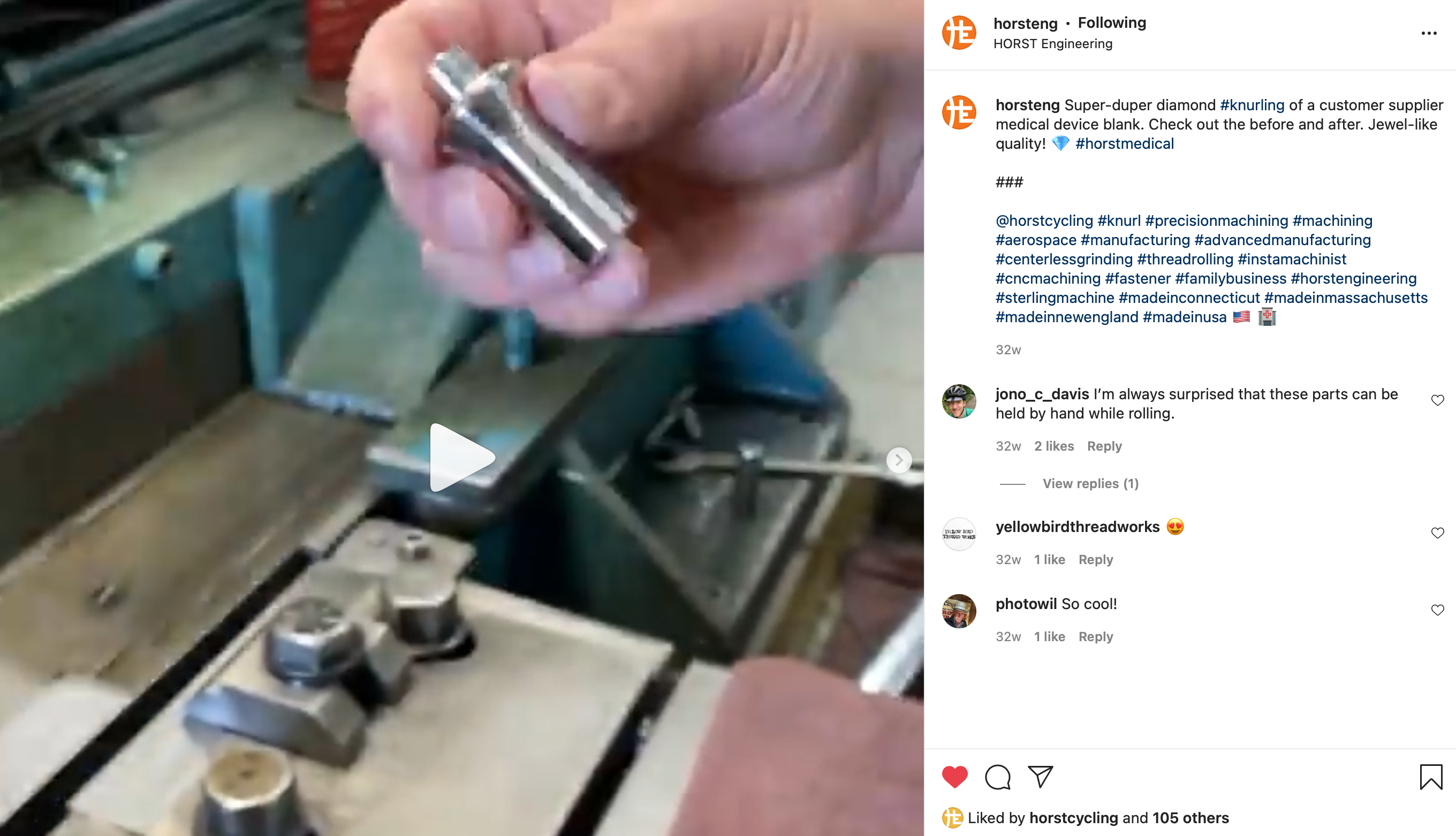

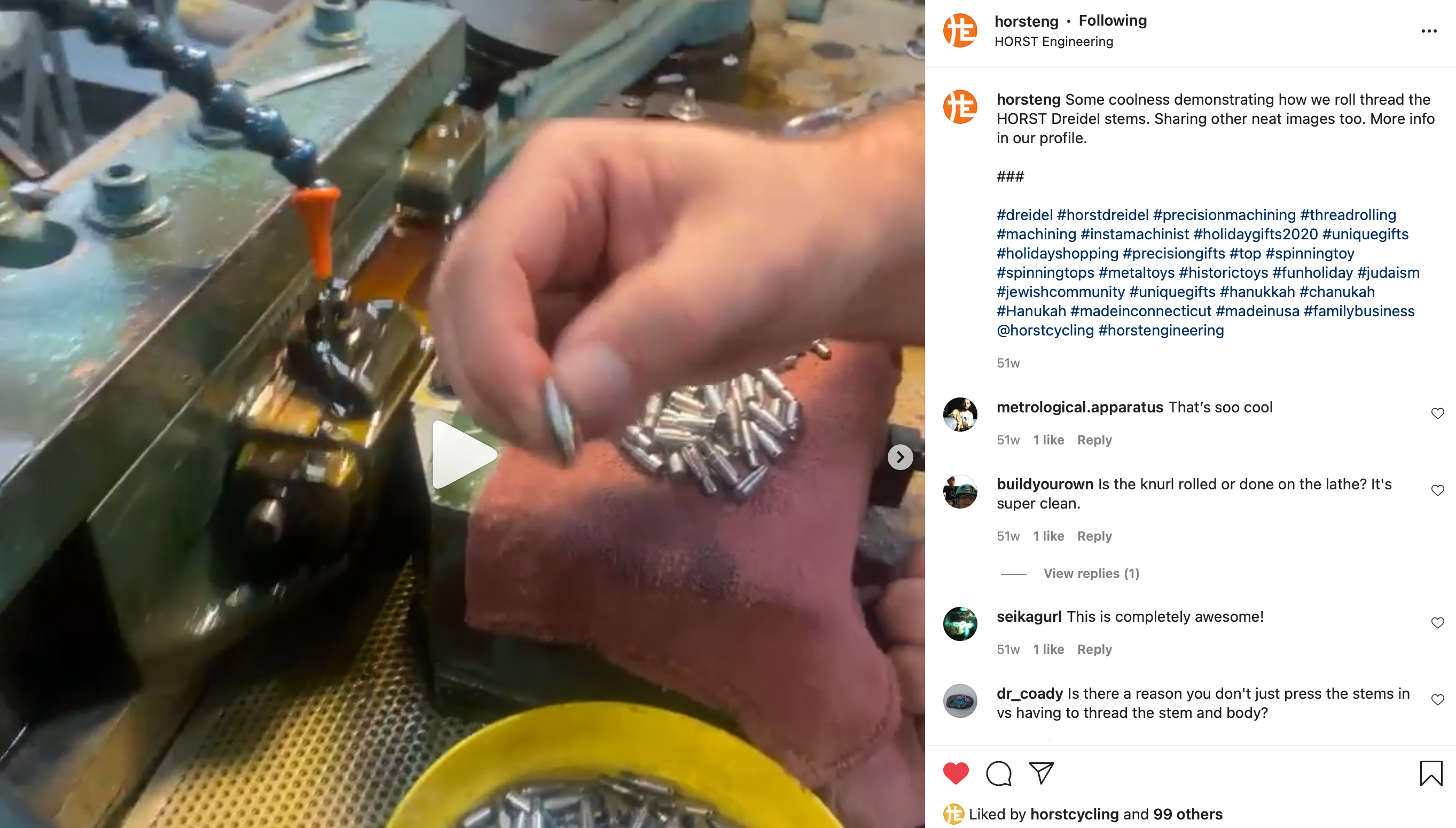

The next operation is to roll form the diamond knurl which serves as the grip or “handle.” We do this on a specialized thread rolling machine with steel dies. Our secondary roll knurling process is the best in the world and we use a similar process to make medical device handles including orthopedic tooling. Many doctors prefer a finely knurled handle for sure grip. Your dreidel stem gets the same treatment.

Roll knurling is awesome. Check out the Instagram video to see it done.

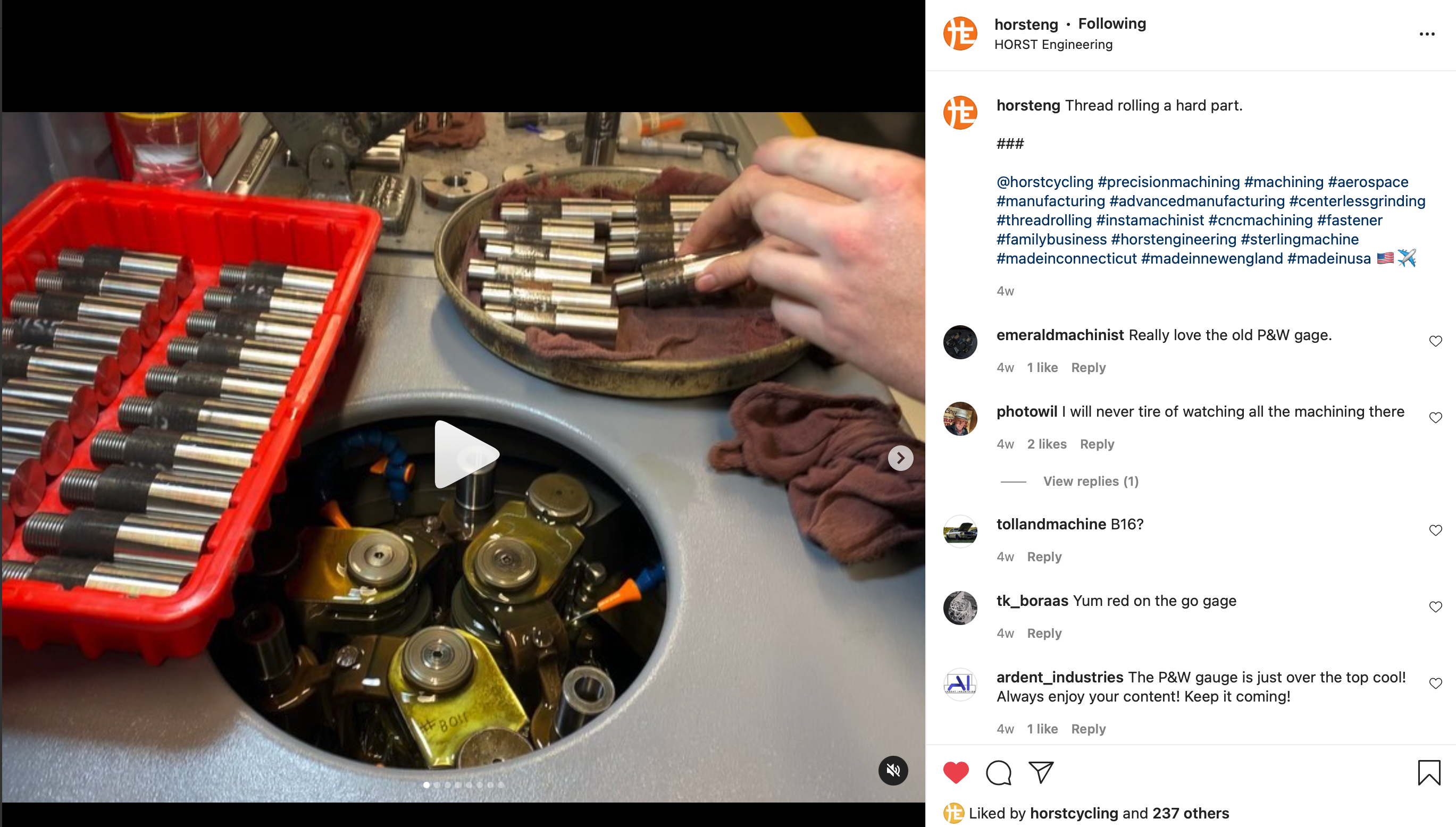

The stem threads are also formed on a thread rolling machine. Rolled threads are 50% stronger than cut or ground threads and they are very precise. Rolled threads are required on the highest quality safety critical fasteners found in jet engines and other aircraft components. They are also used in Formula 1 race cars and in other leading edge motorsports applications. You should have confidence that your HORST Dreidel stem threads will NEVER fail.

Thread rolling is really cool. Check out the Instagram video to see it done.

The final stem operation is to dot peen mark the HE logo on the face. When you put your name on a critical component, its a sign that you stand behind the quality.

The Stand: we turn the stands complete on either a CNC Swiss screw machine or a CNC lathe.

After a tumble deburring process, we also dot peen mark them with our name and logo.

All of these processes are done with the same quality, craftsmanship, and precision that goes into our other components.

If you just haven’t seen enough cool thread rolling videos, here is one more from Instagram. This is the actual HORST Dreidel stem being rolled.