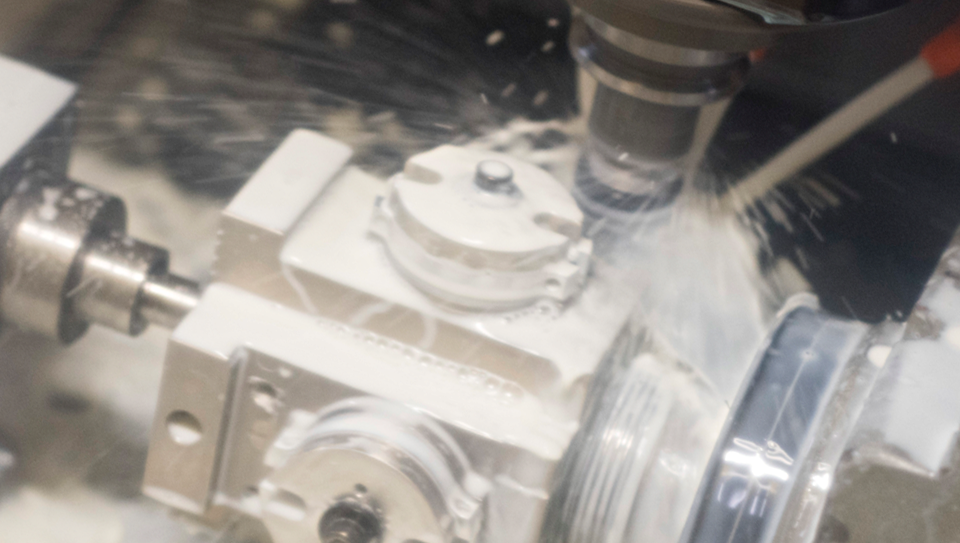

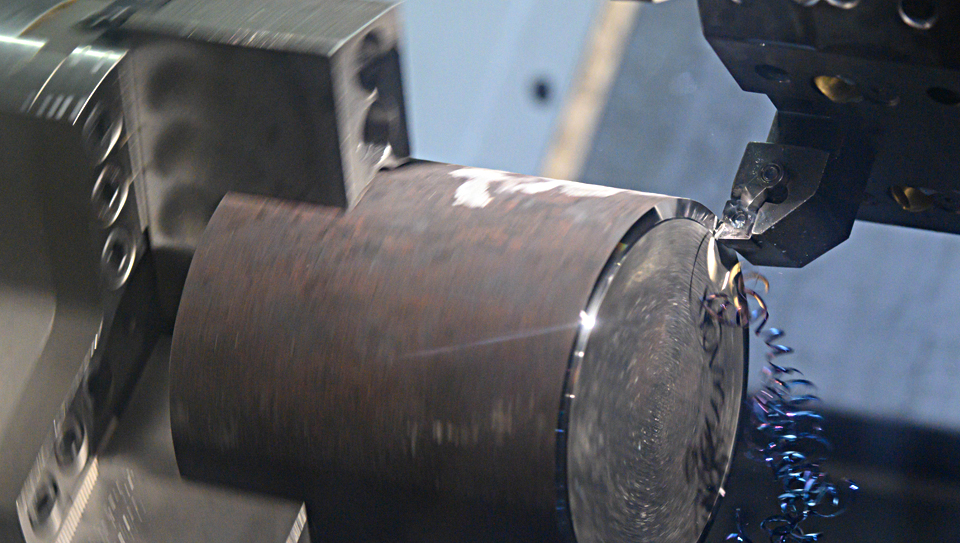

We use advanced manufacturing processes to produce the highest quality precision machined components. Our core product families include parts that are typically less than 8.00 inch diameter or cube, and our sweet spot is 3.00 inches and smaller.

Round bar stock is our most common material shape but we also work with shaped bar, tubing, extrusions, plate, and small castings.

Core Processes

• Swiss screw machining • Turning • Milling • Thread Rolling • Centerless Grinding (in-feed and thru-feed) • Cylindrical Grinding • Honing • Assembly

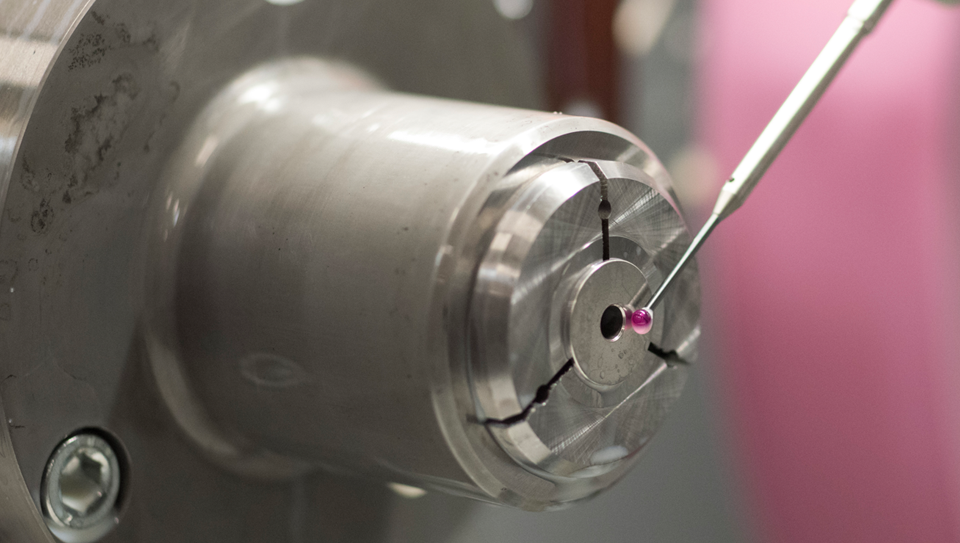

We operate some of the most advanced CNC machining equipment available and invest in the best tooling and gaging. Our equipment is modern and multi-axis with super-precision capabilities. We routinely turn parts within tolerances of .0002 inch and grind parts within .00005 inch. In addition to thread rolling our own products, we perform the process as a service on customer supplied parts. See our Thread Rolling Services page for more information.

Part Marking

In addition to marking our own products, we perform part marking as a service on customer supplied parts. Our in-house part marking capabilities support aerospace requirements.

• Dot-Peen Marking • Electrolytic Etch Marking • Roll Marking • Ink Marking

Full Service Logistics

We manage a diverse and dedicated supply chain. Our region has one of the largest concentrations of precision manufacturing companies in the world.

We manage the end to end supply chain for customer products that require special processes. Our major outsourced processes fall in four major categories:

• Heat Treatment • Coatings • Testing • Grinding, Forming, and Nonconventional Machining

See a full line card for a complete list of the advanced manufacturing processes associated with our parts.