This summer, HORST Engineering proudly hosted a group of interns who brought fresh ideas, technical skill, and curiosity to our team. Our two Engineering Interns and one Quality Assurance Intern made a real impact, contributing to projects that not only advanced their learning but also strengthened our operations.

One of the major projects tackled by our Engineering Interns was the Pin Cell Redraw, an initiative aimed at providing new operation sheets for 800 pins. While the task was technical in nature, the broader purpose was clear. The group was tasked with creating uniform drawings, improve communication on operation sheets, limit misinterpretation and increase efficiency. This also opened opportunities to assign more jobs to our dedicated Swiss machines, enhancing production capacity.

The project touched multiple areas of the business:

- Developing 3D part models with partial design tables filled out by Engineering.

- Adding and verifying part data for each configuration, including dimensions, materials and production notes sourced directly from customer drawings.

- Verifying materials and stock diameters with the Purchasing team.

- Ensuring every drawing passed through a rigorous three-stage review process that included Overall Review, Engineering Approval, and Quality Review.

If approved, the drawing was sent to production. If rejected, it was revised and resubmitted until it met standards. The project was officially completed on July 23, 2025, and since then, pins have been programmed with some even making their way into production.

This project was a true team effort that gave our interns exposure to engineering design, cross functional collaboration, and the importance of precision in aerospace manufacturing.

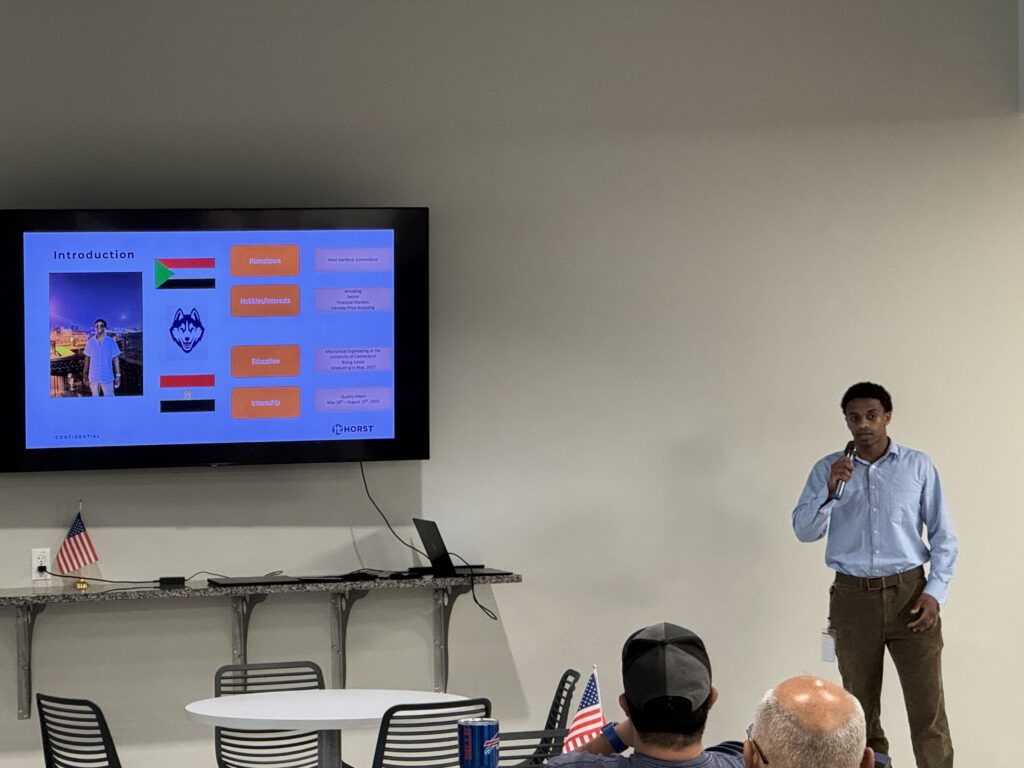

Our Quality Assurance Intern focused on critical processes within inspection and nonconformance management. This led to opportunity with gaining hands-on experience in Quality Job Releases, First Article Inspections (FAIs), and Discrepant Material Reports (DMRs).

In the DMR process, they worked through the following steps:

- Receiving nonconforming parts from inspectors.

- Confirming nonconformances.

- Registering the nonconformance in Epicor and assigning a DMR number.

- Placing the parts in the appropriate Clinic Zone for review.

Through this work, the intern developed technical skills while sharpening attention to detail, problem solving, and process improvement. They also highlighted how much they valued the collaboration and teamwork inherent in the quality process.

Our 2025 Internship Program was more than a summer experience, it was an opportunity for students to apply classroom knowledge in a high tech, ultra precision, aerospace environment. We’re proud of the work our interns accomplished and the professionalism they brought to our team. As they return to school and move forward in their careers, we’re confident they’ll carry these experiences with them.

Thank you to our interns for a successful summer! You’ll always be part of the HORST Engineering story.