For the second year, we sponsored a University of Connecticut Management for Engineering and Manufacturing Senior Design Program project. MEM is a fantastic program that helps prepare engineering students for rewarding careers.

The UConn Management & Engineering for Manufacturing (MEM) major is an independent academic major that is part of both the College of Engineering and the School of Business. MEM students gain critical business and engineering skills, learn how to design solutions, and become effective team leaders. At graduation, they are part of an elite cohort with two tassels hanging from their cap, leaving with a B.S. degree conferred by both schools, total enterprise vision, and well-rounded knowledge of production in manufacturing and the service industries.

UConn says that the program produces some of the brightest, most talented leaders for the technical world. MEM students have a range of skills including technical engineering skills, and finance and accounting, project management, marketing, six sigma, and supply chain. Senior Design is a capstone course during which students work on teams with businesses, manufacturers, and other organizations to complete a project given by the sponsor. Sponsors present a challenge or idea and work with a student team to create the solution. Sponsors gain access to UConn faculty, trained student engineers, as well as first-hand experience working with students who may become future employees. At the same time, students learn to work collaboratively in a real world setting while producing periodic reports on their ideas, strategy, techniques, and progress. Students begin by researching the problem, brainstorming a range of solutions, and traveling to the sponsor’s site to learn more about the sponsor and project.

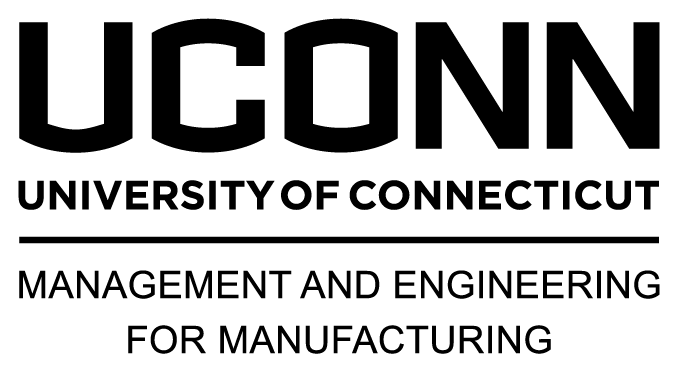

During the 2022-2023 school year, we sponsored an automation study for some of our processes. In 2023-2024 our sponsored project was titled “Modernizing Raw Material Marking and Inventory System to Enhance Traceability.” Four students worked with members of Team HORST to take an old process and update it to a standard that is more representative of our state-of-the-art factory. For years, we have identified and inventoried our raw material (bar stock) with handwritten tags. The process is vital because it maintains the traceability required in the industries that we serve.

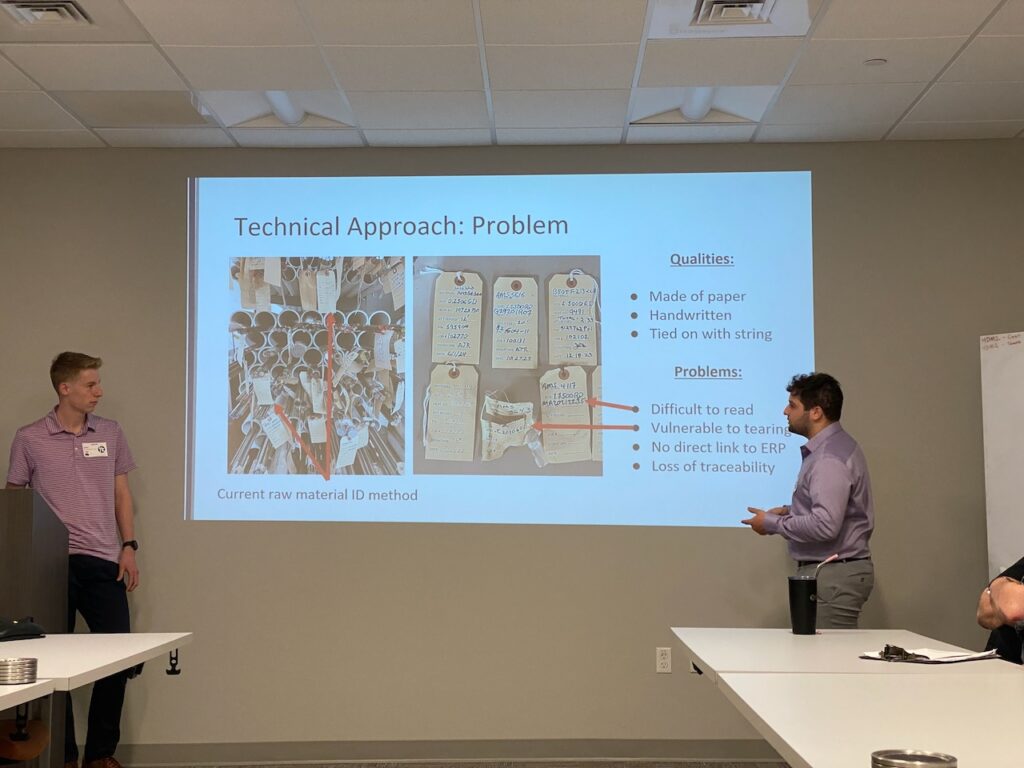

We have thousands of unique raw material types and sizes, and we challenged the MEM students to help us make this process better. They did the research, design, testing, and sourcing – ultimately recommending a solution that would work for small diameter bar stock. The solution will also leverage the data already available in our ERP system and incorporate modern 2D bar coding that works with our existing computer tablets. The team demonstrated improved efficiency and long-term cost savings in a real-world environment. Last week, along with the other MEM teams, they presented the results at a fair on the Storrs campus. This week they visited us to share the presentation. Implementation of the new system will now fall to our team, but chances are we will get help from our summer interns to accelerate our conversion to the new system.

Kudos to the MEM team #05 and our staff for this fruitful collaboration. We wish them good luck as they graduate later this month and begin the next chapter of their lives. We are already looking forward to the 2024-2025 program.