Thread Rolling and Grinding Services

High technology industries, including aerospace, defense, power generation, and motorsports, require threads with stronger physical characteristics, higher accuracy, and excellent surface finish.

Thread Rolling and Grinding Services

High technology industries, including aerospace, defense, power generation, and motorsports, require threads with stronger physical characteristics, higher accuracy, and excellent surface finish.

What is Thread Rolling?

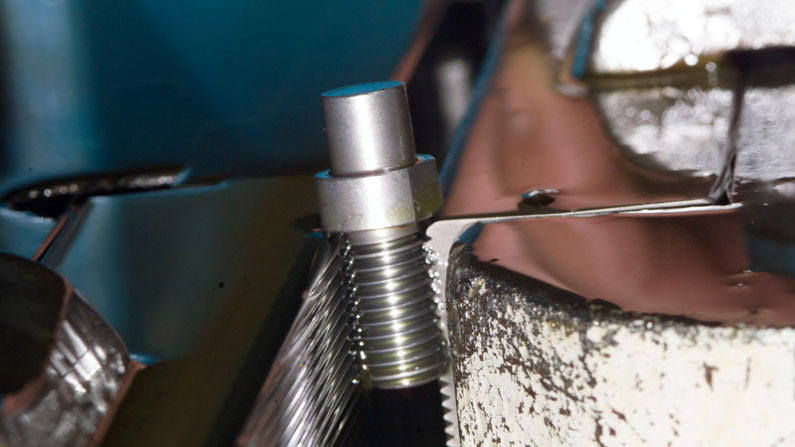

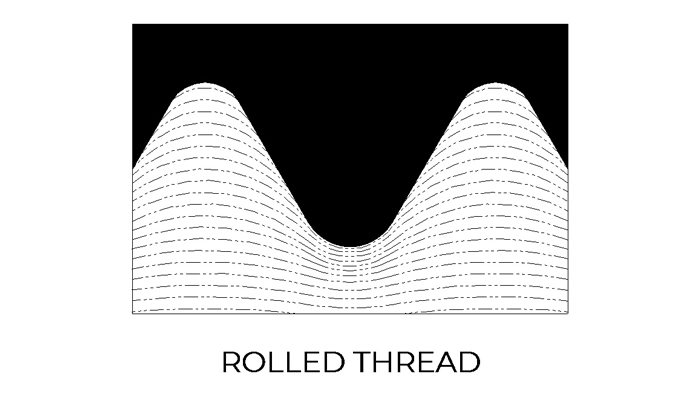

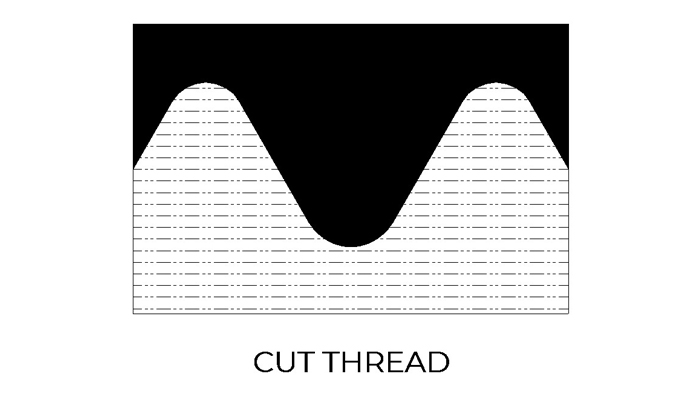

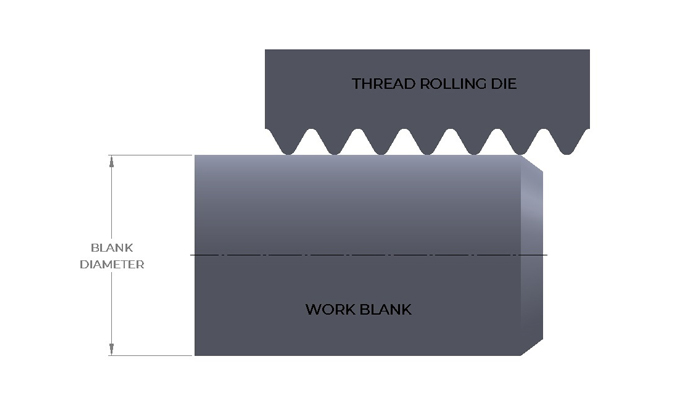

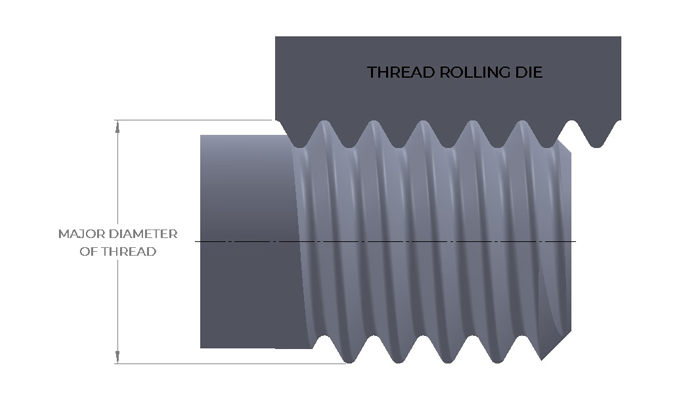

Thread rolling is a cold forging (or forming) process where hardened steel dies are matched and set to penetrate with force in order to reshape the surface of a round diameter into a thread form. Our extensive “How It Works” note, explains the thread rolling process, it’s advantages, and how we help customers engineer their parts to accommodate rolled threads.

What is Thread Rolling?

Thread rolling is a cold forging (or forming) process where hardened steel dies are matched and set to penetrate with force in order to reshape the surface of a round diameter into a thread form. Our extensive “How It Works” note, explains the thread rolling process, it’s advantages, and how we help customers engineer their parts to accommodate rolled threads.

Roll Threading

Capabilities and Approvals

Thread types: 60º thread form/machine screw type threads, Safety Critical Threads

Forms: UNR, UNF, UNC, UNJ, UNJF, UNJC (classes 1A, 2A, 3A, 5A)

Metric forms: ISO and DIN (classes 6g and 4g6g)

Sizes: .078 inch (2mm) to 2.500 inch (63mm)

Material Hardness: Up to Rc45 depending on material type and size

Approvals include: AS Specifications (e.g. AS7460, AS7466), Pratt & Whitney Aircraft, GE Aviation, Collins Aerospace, Kaman Aerospace, Bell, SpaceX

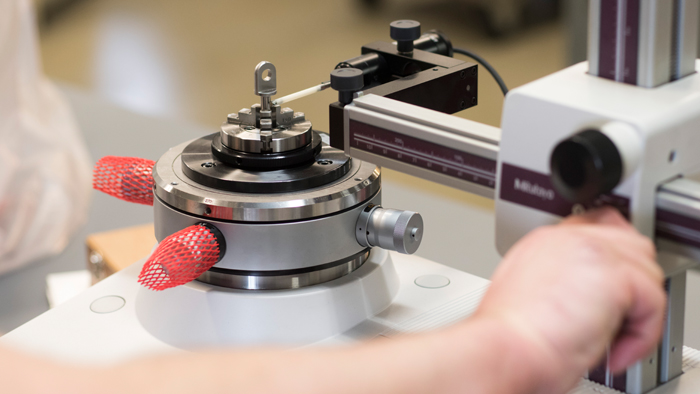

Thread Inspection

We maintain a large inventory of English standard and metric thread gages. Typical industry specifications include AS8879, MIL-S-7742, Handbook H28, and ANSI specifications.

Thread Laboratory & Testing

Our in-house laboratory performs metallographic examinations of rolled threads to aerospace, military, and customer specifications. We test for external and internal defects.

Centerless and Cylindrical Grinding

The highest quality threads are produced from the highest quality blanks. Most customers supply their machined components at a specified oversized diameter. Then we develop the correct size and grind the finished diameter as part of our preparation process.

We also offer centerless and cylindrical grinding services for non-threaded components.

Centerless and Cylindrical Grinding

The highest quality threads are produced from the highest quality blanks. Most customers supply their machined components at a specified oversized diameter. Then we develop the correct size and grind the finished diameter as part of our preparation process.

We also offer centerless and cylindrical grinding services for non-threaded components.

Knurling

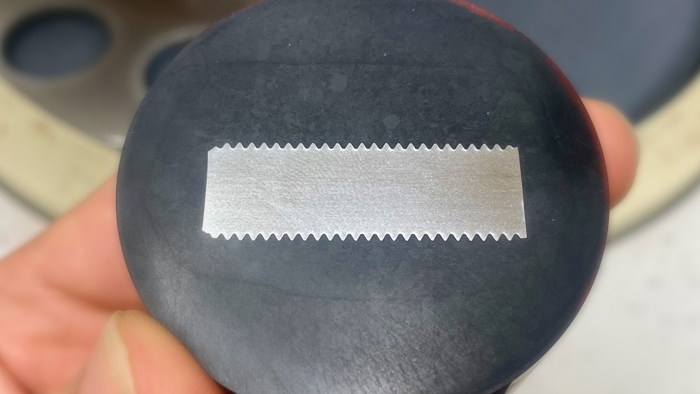

Thread rolling equipment is well suited for producing high quality knurls (straight, diagonal, and diamond). Knurls are essential characteristics for tooling and components in a variety of industries, but especially important for surgical and other medical tooling and devices.

Rolled knurls are superior in finish, form, and dimensional consistency to knurls formed by cutting or bump rolling on lathes and screw machines. Let us help you with your knurling requirements.

Knurling

Thread rolling equipment is well suited for producing high quality knurls (straight, diagonal, and diamond). Knurls are essential characteristics for tooling and components in a variety of industries, but especially important for surgical and other medical tooling and devices.

Rolled knurls are superior in finish, form, and dimensional consistency to knurls formed by cutting or bump rolling on lathes and screw machines. Let us help you with your knurling requirements.

Roll Knurling

Knurl Types: Circular and Diametral Pitch, Straight, Diagonal, Diamond

Circular Pitches/TPI (teeth per inch): 12, 16, 20, 25, 30, 35, 40, 50, 80, special

Diametral Pitches (DP): 64, 96, 128, 160, special

Sizes: .040 inch (1mm) to 1.500 inch (38mm)

Material Hardness: Up to Rc42 depending on material type and size

See our Thread Rolling, Roll Knurling, & Grinding Services Line Card for a more technical summary of our capabilities.

See our Thread Rolling Blank Reference Chart for helpful tips on how to engineer your parts to accommodate rolled threads.

Dispel myths, overcome thread-induced anxiety, and learn more by consulting our Thread Rolling White Paper.

See our Thread Rolling, Roll Knurling, & Grinding Services Line Card for a more technical summary of our capabilities.